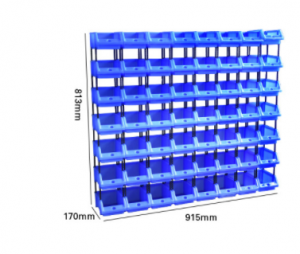

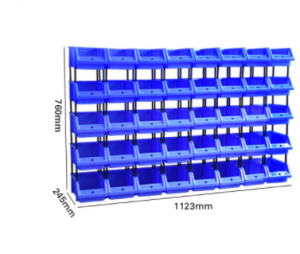

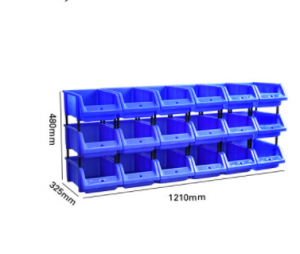

| product type | Plastic storage bin |

| Shape | rectangle |

| Style | Modern, Simple |

| Material | plastic |

| Plastic Type | PP |

| Stacking load | 5-50kg |

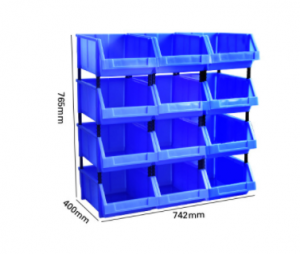

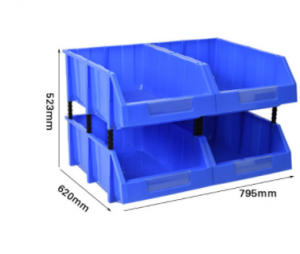

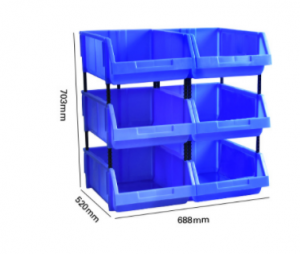

| Size | 742*400*765mm 915*170*813mm |

| Color | Red, yellow, green, blue or customized |

| Usage | Storage |

| Feature | Reinforced and thickened, strong bearing capacity, beautiful and fashionable |

| Logo | Injection |

| Samples Time | 7-15 days |

| Packing | Carton |

| MOQ | 1000pcs |

| Payment Terms | T/T, L/C |

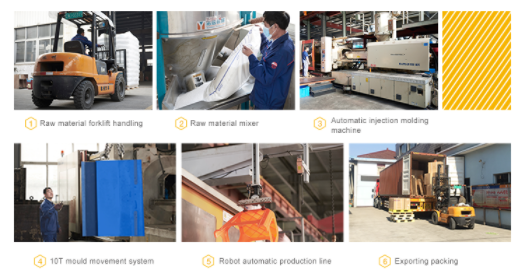

What to pay attention to when making plastic storage box molds

1. The reasonable structure design of Sino Mould can provide product quality and output.

2. It has a better cooling system to reduce the product molding cycle.

3. Good polishing effect to improve the surface quality of the product and smooth demoulding.

4. The robot can be used to complete the entire production process to improve the entire production status and product quality of the product.

1. The wall thickness should be as uniform as possible, and the draft angle should be large enough.

2. The transition part is gradual, smooth transition and avoid sharp corners.

3. Gate. The runner should be as wide as possible, thick and short, and the gate position should be set according to the shrinkage condensation process, and a cold well should be added if necessary.

4. The surface of the mold is smooth and clean, with low roughness (preferably lower than 0.8)

5. Exhaust holes and grooves must be sufficient to discharge air and gas in the melt in a timely manner.

6. Except for PET, the wall thickness should not be too thin, generally not less than 1mm.