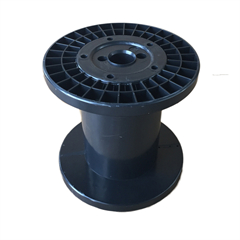

Plastic bobbin can be shaped easily. It’s also one of the most important commercial polyester materials on the market. It’s a semi-aromatic thermoplastic that can be molded with ease and thermoformed. The material has several great attributes, like high strength and toughness, as well as heat resistance. Unsurprisingly, it’s perfect for industrial applications. The resin can be used to make both electrical and auto parts. When it is reinforced, the product can be used in sockets, switches and handles. Due to its high tensile strength, the material can be worked with standard metalworking tools after configuration. It also affords low levels of friction against metallic surfaces. Combined with its high durability, it is frequently used to cast bearings or gears that require long term operation.

There are something you need to know about the plastic bobbin:

1、Plastic bobbins can bulge if filled with too much tension or too tightly.

Filling a sewing machine bobbin too tightly can make a plastic bobbin bulge. This is hard to see the problem, but the bobbin ends up too tall for machine and will cause an awful mess in the bobbin area.

2、Plastic bobbins and metal bobbins of the same size can not be swapped.

Machines are set for a very precise tension setting. If they are set for a lighter plastic bobbin, the tension will change if a heavier metal bobbin is used.

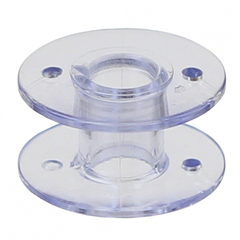

3、You must use the bobbins that are made for your machine

Just because you like the color blue does not mean you can use these bobbins. These bobbins are made specific for a husqvarna viking designer epic sewing and embroidery machine.